1. Oil pressure and temperature management

1. When the filter is blocked and the pressure difference between the front and rear oil pipes is significant, lubricating oil can be supplied through the bypass and the filter should be cleaned as soon as possible, but this measure should be limited to 2-3 hours;

2. If the oil temperature is low or the oil switch is not turned on, resulting in abnormal operation of the oil pump and no display on the oil gauge, you need to heat the oil immediately, turn on the switch, and repair or replace the oil pump if necessary;

3. In winter, the oil temperature is too low, the safety valve fails, the pump flow is too large, etc., which may cause the cone to rise. At this time, it is necessary to heat the oil, adjust the safety valve, or consider replacing the oil pump.

2. Feeding and lubrication maintenance

When feeding, ensure uniform and continuous feeding, avoid too much or too little, especially materials with a lot of fine particles or high humidity require special attention. When the lubrication conditions are not good, the lubricating oil should be checked and replenished in time. If a bearing or ball bearing fails, it must be replaced in time.

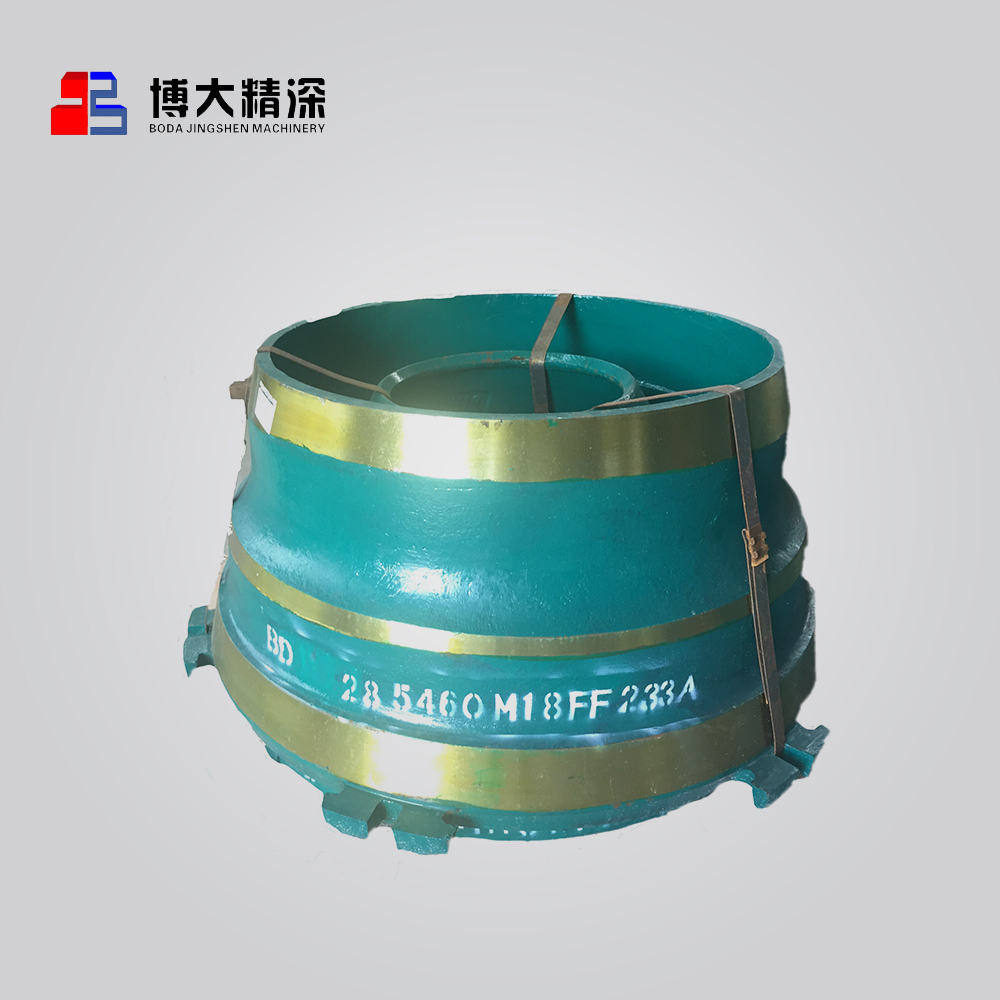

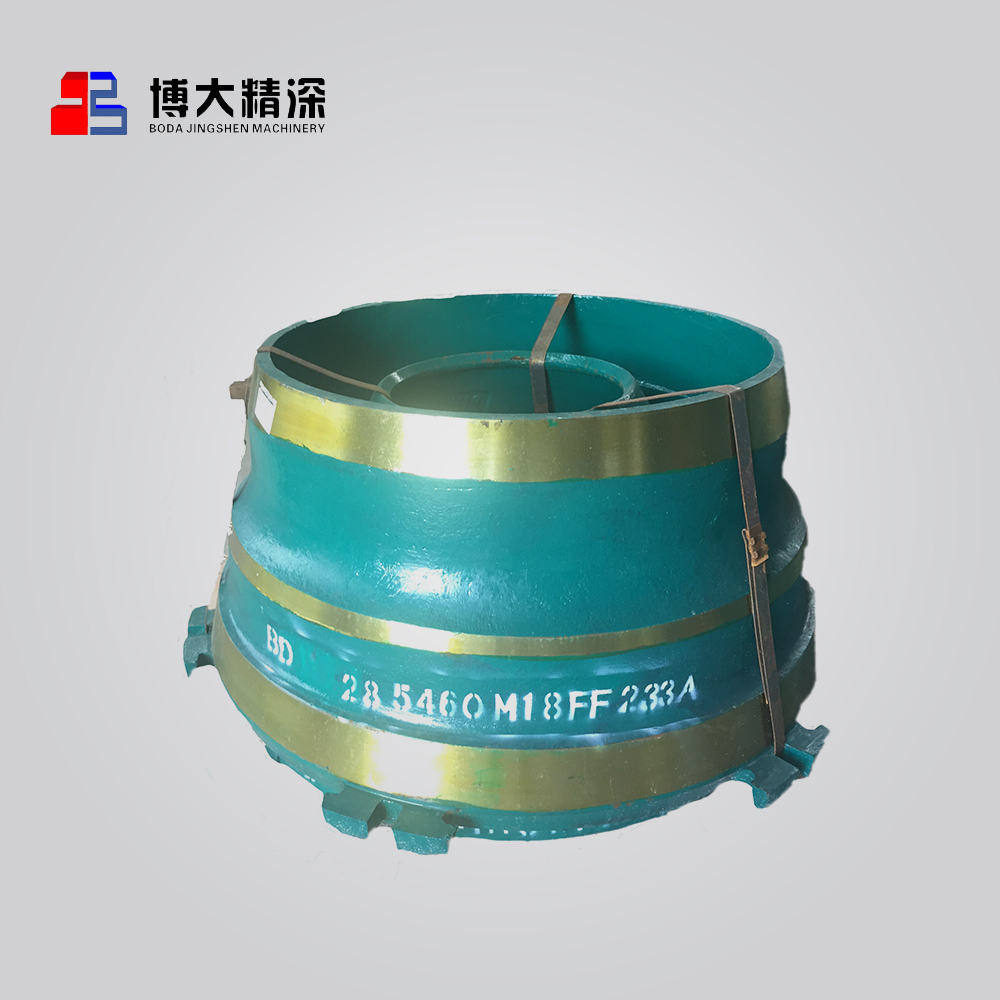

3. Cone bushing wear

Due to the high-speed rotation of the cone and the strong crushing force, the bushing is susceptible to wear such as cutting, plastic deformation, fatigue, etc. Therefore, regular inspection and replacement of bushings is essential.

4. `Speed Car` Failure and Treatment

`Flying` failure is often caused by inner wall wear of the liner, improper installation or excessive wear. In addition, insufficient oil film strength between the spindle and bushing may also cause this problem. Solutions include ensuring the appropriate clearance between the inner and outer holes of the taper sleeve and using molten zinc alloy to secure the taper sleeve and shaft sleeve.

5. Excessive wear and prevention of conical teeth

Excessive wear is often caused by defects in the protective device, feeding materials beyond the equipment's handling capacity, or mismatched drive motors. Preventive measures include adding iron removal equipment, regularly checking the content of metal elements in oil tanks, and optimizing operating procedures.

6. Adjustment circle beating problem

In order to avoid the beating of the adjustment ring, the size of the feed particles should be strictly controlled to ensure that non-crushed materials do not enter the crushing chamber. Before starting, it is necessary to comprehensively check whether the pitch of the adjusting ring and locking ring is reasonable, and optimize the design of the feeding funnel.

7. Molten iron overflow and instant foaming treatment

Once overflow or instantaneous foaming of molten iron occurs, the hydraulic automatic iron passing system should be started immediately to eliminate the fault. At the same time, metal detectors were added to monitor the iron passing situation of the unit in real time to prevent the unit from shutting down.

8. Lubricant failure prevention

Check the labyrinth seal regularly to ensure a good seal. After long-term use, the performance of the lubricating oil decreases and needs to be replaced in time.

9. Vibration control of crusher

Reduce the vibration of the crusher through accurate feeding, adjusting the discharging angle, optimizing the fine particle size and viscosity of the feed. For vibrations caused by the sinking of the cone body, it is necessary to disassemble, inspect and replace relevant parts.

1. Oil pressure and temperature management

1. Oil pressure and temperature management