Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1.1 Multi-cylinder structure

Multi-cylinder hydraulic cone crusher refers to multiple hydraulic cylinders distributed around the circumference of the frame. This structure can realize the integration of the upper and lower frames during the crushing process, as well as the retreat protection of unbreakable objects and the cavity clearing function of sudden shutdown. The hydraulic cylinder for cleaning the crushing cavity has a long stroke and is independent of liner wear. It can reduce the cleaning workload and clear the cavity quickly, thereby shortening downtime. Compared with the single-cylinder hydraulic cone crusher, there is no need to remove the connecting bolts of the upper and lower frames under the same working conditions, and the upper frame can be easily opened, which is labor-saving and convenient.October 11, 2024

October 09, 2024

At present, with the construction of national infrastructure and the recently approved rail transit, it is expected that this year's infrastructure market will still be a year of hard work. The...

The production capacity of the impact crusher directly affects the economic benefits of the overall production line. Today, I will share four tips for effectively improving the counter-attack...

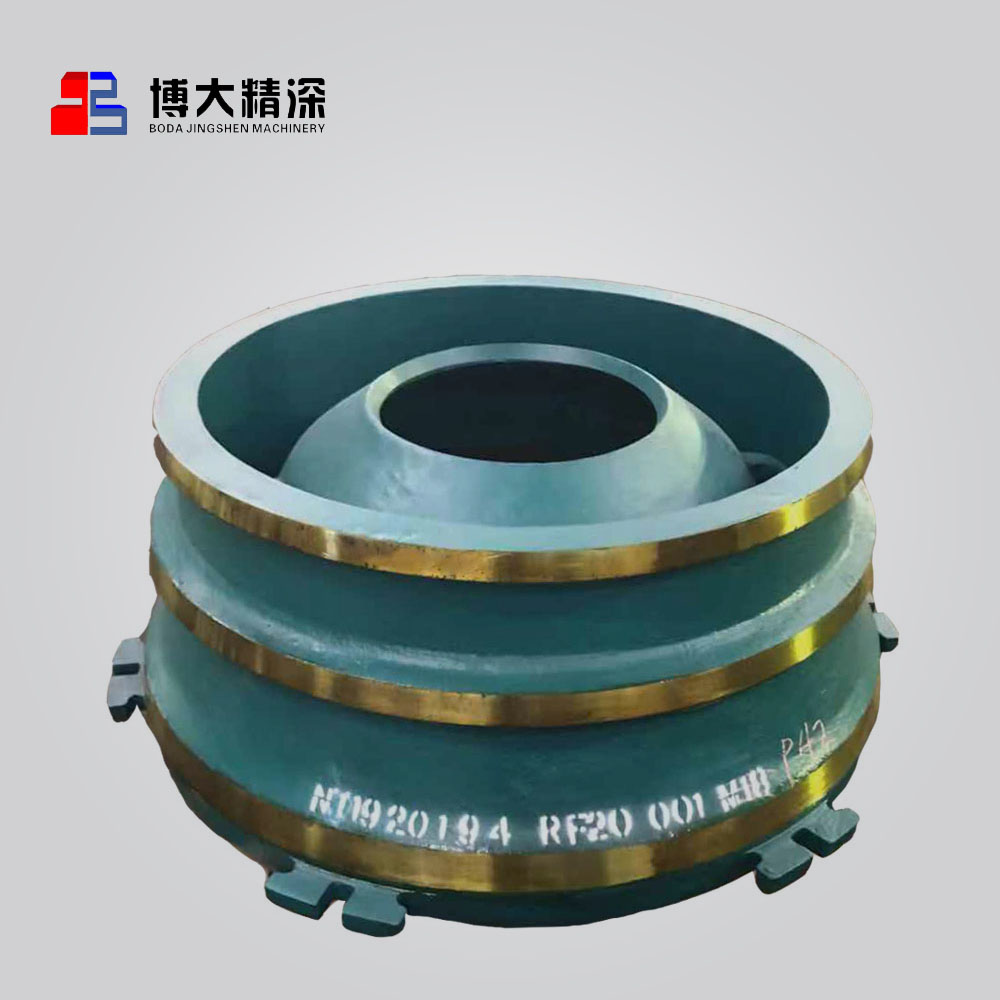

Basic Information Of Cone Crusher Cone crusher is a crusher suitable for metallurgy, construction, road construction, chemical and silicate industries. According to the different crushing principle...

Spare parts statistics statistical of spare parts refer to the statistical tables based on the models and specifications of spare parts. From the table, it can be seen that the spare parts of such...

Email to this supplier

October 11, 2024

October 09, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.